#Manufacturing Traceability

Explore tagged Tumblr posts

Text

Manufacturing Traceability Solutions: Ensuring Quality and Compliance at Every Step

Manufacturing traceability solutions provide companies with the ability to monitor and track every step of the production process, ensuring complete visibility and control. Our sophisticated systems allow manufacturers to record raw material usage, track production stages, and monitor final products, which enhances quality control, minimizes waste, and ensures adherence to regulatory standards. By utilizing real-time data and comprehensive records, businesses can quickly pinpoint and address challenges, boost operational performance, and improve product safety. From automotive to electronics and consumer goods, our traceability solutions are designed to optimize workflows and uphold high standards across the supply chain.

#Manufacturing Traceability#manufacturing traceability software#Manufacturing Traceability Solutions

0 notes

Text

Food Traceability Software with Batch Control: Ensure Quality and Compliance

Food traceability software with batch control helps food manufacturers and suppliers monitor and trace each batch of products from raw materials to final delivery. This software streamlines tracking, ensuring compliance with safety regulations and quality standards, and providing full visibility into the supply chain. With batch control, companies can quickly identify and address any contamination or quality issues, reducing waste and minimizing recall risks. The software supports efficient inventory management, real-time data access, and detailed reporting, helping companies maintain trust with consumers by guaranteeing product safety and transparency at every step.

#Food Traceability Software#food traceability#Food Traceability Software with Batch Control#manufacturing traceability

0 notes

Text

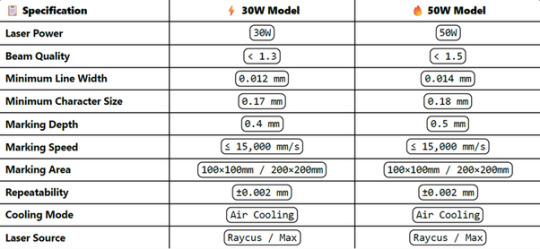

Empowering Smart Manufacturing: The Rise of Fiber Laser Marking Machines

As industries rapidly shift toward customization, miniaturization, and automation, the demand for high-precision marking and engraving technologies is more critical than ever. Fiber laser marking machines have emerged as a game-changing solution, delivering unmatched speed, accuracy, and long-term durability.

These systems are engineered for permanent marking of metals and select non-metals, making them indispensable in the electronics, automotive, medical device, and industrial manufacturing sectors.

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine is an advanced, third-generation system that utilizes a fiber laser source and high-speed galvanometric scanners to mark, engrave, or etch surfaces with extreme precision. Operating at a wavelength of 1064 nm, these machines are ideal for marking stainless steel, aluminium, brass, and certain industrial plastics, ensuring clear, permanent identification marks.

Key Applications in Lithium-ion Battery Manufacturing

In the world of lithium-ion battery manufacturing, where precision, cleanliness, and traceability are paramount, fiber laser machines meet and exceed industry requirements:

Laser Cleaning of Cell Tabs and Terminals Removes oxides and contaminants from battery tabs, busbars, and cell terminals without damaging the surface, ensuring optimal electrical contact and weld integrity.

Traceability Marking on Cell Casings and Modules Permanently engraves QR codes, barcodes, and serial numbers on battery cells, modules, and pack casings for complete lifecycle traceability.

Marking Insulation Layers and Protective Films Enables non-invasive marking on insulation films and separators, aiding component identification during automated assembly processes.

Core Benefits of Fiber Laser Marking Machines

Ultra-Fine Marking Precision – Ideal for detailed micro-text, data matrix codes, and alphanumeric identifiers.

Fast, Continuous Operation – Speeds up production lines by minimizing cycle time.

No Consumables – A cost-effective, eco-friendly solution suited for cleanroom environments.

Maintenance-Free Design – Delivers up to 100,000 hours of reliable operation.

Air Cooling System – Simplifies system integration and reduces operational complexity.

Broader Industrial Applications

Electronics Industry – Circuit boards, microchips, mobile phone casings

Automotive Sector – Gears, engine components, VIN plates

Medical Field – Surgical tools, implants, product IDs

Consumer Goods – Watches, designer accessories

Tool Manufacturing – Precision tools, calibration equipment

Conclusion

Fiber laser marking machines are revolutionizing the landscape of smart manufacturing by delivering the precision, efficiency, and traceability that modern industries demand. Their critical role in lithium-ion battery production—from laser cleaning to traceability marking—ensures safer, smarter, and more streamlined production lines.

Whether you're handling microscopic components or large-scale battery packs, fiber laser technology empowers your operations with consistent marking and cleaning processes essential for high-volume, high-precision manufacturing.

#fiber laser marking machines#smart manufacturing#laser cleaning#traceability in battery production#laser engraving technology#high-precision marking#battery manufacturing equipment#non-contact marking systems

0 notes

Text

Ensure end-to-end traceability software for food manufacturing. This tool enables tracking of every step, helping businesses comply with regulations and maintain safety in food production.

0 notes

Text

See how the HeatSign DE01 Dot Peen Marking Machine delivers deep, permanent markings on carbon steel surfaces. This video demonstrates its powerful engraving capability, ensuring that markings stay clear and visible even after galvanizing, painting, and other surface treatments.

With precision marking and industrial-grade durability, the DE01 is the perfect solution for industries requiring long-lasting identification and traceability. Watch the machine in action and discover how it can enhance your marking process!

🔹 Key Features: ✔ Deep and permanent dot peen marking ✔ Marks remain visible after galvanizing and painting ✔ Ideal for metal fabrication, steel processing, and industrial applications

For more details visit: https://www.heatsign.com/products/dot-peen-marking-machine/

#Technology#HeatSign#DotPeenMarking#DE01#DeepMarking#CarbonSteelEngraving#MetalMarking#IndustrialEngraving#PermanentMarking#Traceability#Manufacturing

0 notes

Text

The Importance of Product Traceability in Modern Supply Chains

Introduction

In today's fast-paced and globalized supply chain environment, product traceability is no longer just a competitive advantage; it is an absolute necessity. Businesses across various industries are turning to product traceability to ensure operational transparency, compliance with regulations, and enhanced customer trust. From tracking the origins of raw materials to monitoring the entire production process and ensuring efficient delivery, product traceability is transforming how manufacturers manage and optimize their supply chains.

What Is Product Traceability?

Product traceability refers to the ability to track the journey of a product through its entire lifecycle, from raw materials to the final delivery. This includes tracking the product during manufacturing, distribution, and transportation. Traceability systems capture and record detailed information at every stage, allowing businesses to track the product’s movement downstream (from production to customer) and trace its origins upstream (raw materials and components).

The value of product traceability lies in its ability to provide transparency and insight into every step of the production and supply chain process. As supply chains become more complex, the importance of product traceability continues to grow.

The Role of Digitalization in Product Traceability

The digital transformation of industries, also known as Industry 4.0, has made product traceability much more efficient and powerful. The rise of technologies such as the Internet of Things (IoT), cloud computing, and artificial intelligence has significantly enhanced the ability to monitor products in real time. Through the integration of these technologies, manufacturers can now track production data at every step and address potential problems before they escalate.

Benefits of Product Traceability for Manufacturers

Product traceability offers a multitude of benefits for manufacturers, particularly in industries like automotive, pharmaceuticals, and food production, where safety, quality, and regulatory compliance are critical. Below are the key advantages:

Enhanced Quality Control: With product traceability, manufacturers can pinpoint the source of any defects or inconsistencies in production. This allows them to quickly isolate the issue, prevent further defects, and improve overall product quality.

Efficient Recalls: If a product issue arises, product traceability enables manufacturers to trace the defective batch back to its source and quickly remove it from circulation. This is especially critical in industries such as food and pharmaceuticals, where faulty products can have serious public health consequences.

Compliance with Regulations: Many industries require manufacturers to maintain detailed records of a product’s history. For instance, the automotive industry demands strict adherence to traceability to ensure the safety of vehicles. A robust traceability system helps businesses meet regulatory requirements and avoid penalties.

Overcoming Challenges in Implementing Product Traceability

While the benefits of product traceability are clear, implementing an effective traceability system comes with its own set of challenges. Some of the common challenges businesses face include:

High Initial Costs: Implementing traceability systems can require significant investments in hardware such as IoT sensors, RFID tags, and software platforms. However, the long-term gains in efficiency and compliance often outweigh these initial costs.

Integration with Legacy Systems: Older manufacturing facilities often rely on legacy systems that are not compatible with modern traceability solutions. This creates technological barriers that require upgrades, which can be costly and disruptive.

Managing Complex Data: Product traceability generates vast amounts of data. Effectively processing and analyzing this data can be overwhelming for businesses. Cloud computing and AI-driven analytics can help manufacturers make sense of this data and identify inefficiencies in their operations.

The Future of Product Traceability

Looking to the future, product traceability will continue to evolve alongside technological advancements. One of the most promising technologies for enhancing traceability is blockchain. Blockchain offers a decentralized, tamper-proof ledger that records every transaction and movement of a product through the supply chain. This would provide even greater transparency and security for businesses, enabling them to offer consumers detailed information about the journey of their products.

As consumer demands for safety, sustainability, and transparency grow, businesses that embrace traceability will be better positioned to differentiate themselves in the market. With blockchain and other digital technologies, product traceability will become more streamlined, secure, and efficient.

FAQs

What is product traceability?

Product traceability is the process of tracking a product’s journey through every stage of the supply chain, from raw materials to the final delivery to the customer.

Why is product traceability important for manufacturers?

Product traceability is vital for quality control, efficient recalls, regulatory compliance, and ensuring transparency in the production process.

What role does digitalization play in product traceability?

Digital technologies like IoT, cloud computing, and artificial intelligence enhance traceability by providing real-time data, improving efficiency, and automating many tracking processes.

How does product traceability support sustainability?

Product traceability allows companies to verify that their raw materials are sourced ethically and sustainably, helping reduce the environmental impact of their supply chain.

What are some challenges of implementing product traceability?

Challenges include high initial costs, technological barriers when integrating with legacy systems, and managing the vast amounts of data generated by traceability systems.

What is the future of product traceability?

The future of product traceability includes the adoption of blockchain technology, which provides a secure, decentralized ledger for tracking products and offers greater transparency and accountability.

Conclusion

In conclusion, product traceability is a critical component of modern supply chain management. It not only ensures compliance and quality but also builds consumer trust by providing transparency into the product’s journey. With advancements in technology, businesses have the tools to make their supply chains more efficient and sustainable through robust traceability systems. By embracing these technologies, manufacturers can gain a competitive edge and ensure long-term success in an increasingly complex and demanding marketplace.

0 notes

Text

Food Manufacturing Traceability Software

HACCP Builder's food manufacturing traceability software ensures compliance with food safety regulations by tracking ingredients and finished products throughout the production process. It streamlines record-keeping, enhances transparency, and enables quick identification and resolution of potential safety issues, ensuring product integrity and consumer trust.

#traceability software food industry#best food traceability software#traceability software for food manufacturing#food manufacturing traceability software#food traceability software

0 notes

Text

Illustration photo: Maize kernels being processed for food manufacturing (public domain)

Unveiling the Treasure of West Africa: Maize Grains from Sahel Agri-Sol

July 5, 2024

In the heart of West Africa, where the fertile lands of Mali stretch under the warm African sun, Sahel Agri-Sol cultivates nature's bounty - maize grains that stand unrivaled in quality, flavor, and versatility. As a leading producer and exporter of agricultural commodities, we invite food and cosmetics manufacturers worldwide to discover the transformative power of our exceptional corn.

A Legacy of Excellence

Sahel Agri-Sol's story is deeply rooted in the rich agricultural tradition of Mali. For generations, our farmers have nurtured the land, combining time-honored techniques with modern sustainable practices. This unique approach results in maize grains that not only meet but exceed global standards, offering a product that's truly special in today's market.

For Food Manufacturers: Elevate Your Culinary Creations

Flavor Profile

Our maize grains boast a robust, slightly sweet flavor with nutty undertones - a testament to the unique terroir of West Africa. This distinctive taste can add depth and character to a wide range of food products, setting your offerings apart in a competitive market.

Versatility

From traditional cornmeal and polenta to innovative snack foods and gourmet popcorn, our maize adapts beautifully to diverse applications. Its superior texture and consistent quality make it ideal for:

Nutritional Excellence

Packed with essential nutrients, our maize is a powerhouse of:

For Cosmetics Manufacturers: Nature's Beauty Secret Unveiled

Innovative Ingredients

Unlock the potential of maize in your cosmetic formulations:

1. Corn Silk Extract: Rich in antioxidants, it offers anti-aging and skin-soothing properties.

2. Corn Oil: A lightweight, non-comedogenic oil perfect for moisturizers and hair care products.

3. Corn Starch: An excellent natural absorbent for powders and dry shampoos.

4. Microfine Cornmeal: Gentle exfoliant for body scrubs and facial cleansers.

Eco-Friendly Appeal

In an era where consumers demand natural, sustainable beauty solutions, our maize-derived ingredients offer a compelling narrative. Highlight the purity and origin of your ingredients, connecting your brand to the vibrant agricultural heritage of West Africa.

The Sahel Agri-Sol Advantage

1. Sustainable Cultivation

Our farms employ a blend of traditional wisdom and modern eco-friendly practices, ensuring minimal environmental impact while maximizing yield and quality.

2. Rigorous Quality Control

From seed selection to harvest and processing, every step is meticulously monitored. Our state-of-the-art facilities and stringent testing protocols guarantee purity, consistency, and safety.

3. Flexible Solutions

Whether you need bulk shipments or smaller quantities, we offer customizable packaging options to suit your specific requirements.

4. Year-Round Availability

Our strategic planning and extensive storage facilities ensure a stable supply throughout the year, protecting your production schedules from seasonal fluctuations.

5. Competitive Edge

By choosing Sahel Agri-Sol, you're not just buying superior maize - you're investing in a story of sustainability, tradition, and quality that resonates with today's conscious consumers.

6. Support and Expertise

Our team of agricultural experts and customer service professionals is always ready to assist you, from product selection to logistics support.

Global Reach, Local Impact

By partnering with Sahel Agri-Sol, you're not only elevating your products but also supporting sustainable agricultural practices and contributing to the economic development of West African communities.

Experience the Sahel Agri-Sol Difference

We invite you to discover the unparalleled quality of our West African maize. Contact us today to request samples, discuss your specific needs, or arrange a visit to our facilities in Mali. Let's explore how Sahel Agri-Sol's premium maize grains can revolutionize your product line and captivate your customers.

Bring the golden essence of West Africa to your global products. Choose Sahel Agri-Sol - where quality meets tradition, and innovation embraces nature.

Sahel Agri-Sol

Hamdallaye ACI 2 000,

« BAMA » building 5th floor APT 7

Bamako

Mali

Phone: +223 20 22 75 77

Mobile: +223 70 63 63 23, +223 65 45 38 38

WhatsApp/Telegram global marketing and sales: +223 90 99 1099

Email: [email protected]

Web sites

English https://sahelagrisol.com/en

Français https://sahelagrisol.com/fr

Español https://sahelagrisol.com/es

简体中文 https://sahelagrisol.com/zh

عربي https://sahelagrisol.com/ar

More

#West African maize#premium corn#Mali agriculture#food manufacturing ingredients#cosmetics natural ingredients#sustainable farming#global export#premium grains#traceable supply chain#nutritional corn#corn-based cosmetics#eco-friendly ingredients#innovative food products#African agricultural heritage#customizable solutions#year-round availability#quality control#traditional farming techniques#modern agricultural practices#economic development#conscious consumerism#versatile corn applications#gourmet corn products#maize-derived beauty ingredients#global food industry#international cosmetics market#agricultural commodities#exotic ingredients#culinary innovation

1 note

·

View note

Text

0 notes

Text

hell day hell day hell day. ive never before encountered a customer with traceability to their own specs and drawings as bad as the one im currently dealing with.

overbooked myself like craaaazy this week. i will persevere or i will be dead by saturday. everything in life is 50/50

#they cant even figure out if a surface should be painted bc their drawing is written so poorly#this drawing that is in no way traceable to the actual part number#this drawing that is 3 revisions behind what they brought with them bc they didnt send us the updated drawings as they revised it#this part that has a whole other SEPARATE drawing just for pin installation. w#also with no traceability back to the first drawing#the pin drawing also has conflicting find numbers for the pins to the parts list.#the parts list that is a different dash number than the part number that! dont forget! is no where on the drawing#im gonna tear my hair out#americans actually are better at manufacturing than the rest of the world bc this is a foreign customer and WHAT THE ACTUAL FUCK#reid talks#sorry for shop talk but ohhhh my god

12 notes

·

View notes

Text

Unveiling Precision: The Power of Manufacturing Traceability Software

In the dynamic realm of modern manufacturing, where precision, compliance, and accountability reign supreme, Manufacturing Traceability Software emerges as a game-changing asset. This blog delves into the multifaceted capabilities of this innovative technology, exploring its impact on production processes, quality assurance, and the overall evolution of the manufacturing landscape.

I. Introduction

Manufacturing Traceability Software is a technological marvel that has transformed the way products are made, monitored, and managed throughout the production lifecycle. This system goes beyond traditional record-keeping, offering a comprehensive solution that addresses challenges associated with quality control, regulatory compliance, and supply chain visibility.

II. The Core Functions of Manufacturing Traceability Software

a. Product Traceability

At the heart of Manufacturing Traceability Software is the ability to trace the journey of a product from raw materials to the end consumer. This granular traceability ensures that every component and process is accounted for, minimizing the risk of defects and enhancing overall product quality.

b. Quality Assurance

Ensuring product quality is a non-negotiable aspect of manufacturing. Traceability software facilitates real-time monitoring of production processes, allowing manufacturers to identify and rectify quality issues promptly. This proactive approach not only improves product quality but also reduces the likelihood of recalls and associated costs.

c. Compliance Management

In an era of stringent regulatory requirements, adherence to compliance standards is paramount. Manufacturing Traceability Software automates compliance management by documenting and verifying adherence to industry-specific regulations, ensuring that manufacturers consistently meet the necessary standards.

d. Supply Chain Visibility

A transparent supply chain is a resilient supply chain. Manufacturing Traceability Software provides end-to-end visibility into the supply chain, allowing manufacturers to anticipate disruptions, optimize inventory levels, and enhance overall supply chain efficiency.

III. Benefits of Implementing Manufacturing Traceability Software

a. Improved Product Quality

By systematically tracking and monitoring every stage of production, traceability software significantly enhances product quality. This not only satisfies customer expectations but also bolsters the reputation of manufacturers for delivering reliable and high-quality products.

b. Faster Issue Resolution

In the event of a product quality issue or recall, traceability software expedites the identification and isolation of affected products. This rapid response minimizes the impact on consumers, reduces the scope of recalls, and mitigates potential damage to the brand.

c. Cost Reduction

While the initial investment in traceability software may seem substantial, the long-term benefits far outweigh the costs. Improved quality, reduced recalls, and optimized supply chain processes contribute to significant cost savings over time.

d. Enhanced Brand Reputation

In an era where consumers prioritize transparency and accountability, a commitment to traceability can differentiate a manufacturer in the market. Enhanced brand reputation leads to customer loyalty and positive perceptions, driving long-term business success.

IV. Integration with Other Manufacturing Systems

Manufacturing Traceability Software is designed to seamlessly integrate with other manufacturing systems, such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). This integration ensures a cohesive and interconnected manufacturing environment, where data flows seamlessly between different systems, providing a holistic view of operations.

V. The Future of Manufacturing Traceability Software

As technology advances, so does the potential of Manufacturing Traceability Software. The integration of Internet of Things (IoT) devices, artificial intelligence, and machine learning promises even greater insights into production processes. Predictive analytics and real-time decision-making capabilities are poised to become integral components of traceability software, further enhancing its impact on manufacturing efficiency and product quality.

VI. Conclusion

In the era of Industry 4.0, where digital transformation is reshaping manufacturing landscapes, Manufacturing Traceability Software emerges as a linchpin in ensuring precision, compliance, and efficiency. Its ability to provide end-to-end visibility, facilitate rapid issue resolution, and enhance overall product quality positions it as an indispensable tool for manufacturers navigating the complexities of the modern industrial landscape. Those who embrace the power of Manufacturing Traceability Software are not just investing in technology; they are investing in the future sustainability and success of their manufacturing endeavors.

#Manufacturing Traceability#Manufacturing Traceability Software#Traceability Software#food traceability

0 notes

Text

Manufacturing Traceability Software: Ensuring Quality and Compliance Across Production

Manufacturing Traceability Software offers businesses the ability to track and monitor every stage of the production process, from raw materials to finished products. This powerful solution helps manufacturers maintain quality control, comply with industry regulations, and ensure transparency in supply chains. With real-time data and comprehensive reporting, companies can quickly identify defects, improve efficiency, and enhance product safety. By integrating traceability software, manufacturers gain better visibility into their operations, reducing risks and ensuring that products meet both customer expectations and legal standards.

#Manufacturing Traceability#Manufacturing Traceability Software#food traceability#food traceability software

0 notes

Text

anticiv take of the day: workers have less power in 2024 than they did in the 1800s so you should stop trying to organize them. I make fun of anarchists for refusing to read Marx and Engels but you don't even need to know them. A Dickens novel or a high school history class should be enough to make this post look comically stupid. Never mind that the most successful revolutions did not involve wage laborers withholding their labor but literal feudal peasants.

the post goes on to instead advise disrupting supply chains with direct action. Disrupting supply chains with who? The only kind of adventurist sabotage you could do by yourself to actually make an impact on supply chains (and the post gestures at it, bringing up blackouts) - is shooting at power stations. This is almost the single easy way to get arrested by the FBI or equivalent as a leftist. They wouldn't need to manufacture bullshit RICO charges like they are currently already getting away with doing to the Stop Cop City folks, they can just use the actual terrorism charges they conspicuously avoid every time a Boogaloo shithead shoots at power stations. I'm not saying the deactivated OP or the person who put this post on my dash are feds - but recognize that this is the exact same kind of thing a fed would post. "Don't organize at work, it's too hopeless, commit traceable crimes with as few people as possible."

(I guess OP could also mean arson or bombings? The Weather Underground tried that, look up how it went for them - including the part where they all gave up on radical politics and became beltway Democrats, like every anticiv would do if they were offered the chance to.)

508 notes

·

View notes

Text

"Clothing tags, travel cards, hotel room key cards, parcel labels … a whole host of components in supply chains of everything from cars to clothes. What do they have in common? RFID tags.

Every RFID (Radio Frequency Identification) tag contains a microchip and a tiny metal strip of an antenna. A cool 18bn of these are made – and disposed of – each year. And with demands for product traceability increasing, ironically in part because of concerns for the social and environmental health of the supply chain, that’s set to soar.

And guess where most of these tags end up? Yup, landfill – adding to the burgeoning volumes of e-waste polluting our soils, rivers and skies. It’s a sorry tale, but it’s one in which two young graduates of Imperial College London and Royal College of Art are putting a great big green twist. Under the name of PulpaTronics, Chloe So and Barna Soma Biro reckon they���ve hit on a beguilingly simple sounding solution: make the tags out of paper. No plastic, no chips, no metal strips. Just paper, pure and … simple … ? Well, not quite, as we shall see.

The apparent simplicity is achieved by some pretty cutting-edge technical innovation, aimed at stripping away both the metal antennae and the chips. If you can get rid of those, as Biro explains, you solve the e-waste problem at a stroke. But getting rid of things isn’t the typical approach to technical solutions, he adds. “I read a paper in Nature that set out how humans have a bias for solving problems through addition – by adding something new, rather than removing complexity, even if that’s the best approach.”

And adding stuff to a world already stuffed, as it were, can create more problems than it solves. “So that became one of the guiding principles of PulpaTronics”, he says: stripping things down “to the bare minimum, where they are still functional, but have as low an environmental impact as possible”.

...how did they achieve this magical simplification? The answer lies in lasers: these turn the paper into a conductive material, Biro explains, printing a pattern on the surface that can be ‘read’ by a scanner, rather like a QR code. It sounds like frontier technology, but it works, and PulpaTronics have patents pending to protect it.

The resulting tag comes in two forms: in one, there is still a microchip, so that it can be read by existing scanners of the sort common within retailers, for example. The more advanced version does away with the chip altogether. This will need a different kind of scanner, currently in development, which PulpaTronics envisages issuing licences for others to manufacture.

Crucially, the cost of both versions is significantly cheaper than existing RFID kit – making this a highly viable proposition. Then there are the carbon savings: up to 70% for the chipless version – so a no-brainer from a sustainability viewpoint too. All the same, industry interest was slow to start with but when PulpaTronics won a coveted Dezeen magazine award in late 2023, it snowballed, says So. Big brands such as UPS, DHL, Marks & Spencer and Decathlon came calling. “We were just bombarded.” Brands were fascinated by the innovation, she says, but even more by the price point, “because, like any business, they knew that green products can’t come with a premium”."

-via Positive.News, April 29, 2024

--

Note: I know it's still in the very early stages, but this is such a relief to see in the context of the environmental and human rights catastrophes associated with lithium mining and mining for rare earth metals, and the way that EVs and other green infrastructure are massively increasing the demand for those materials.

I'll take a future with paper-based, more humane alternatives for sure! Fingers crossed this keeps developing and develops well (and quickly).

#I do really wish it could be read by regular scanners already though#that's what I thought at first#and that would've been fucking amazing#but this is still pretty cool#electronics#science and technology#green technology#ewaste#landfill#lithium#lithium mining#human rights#environment#climate action#climate hope#rfid#rfid technology#rfid tags#good news#hope

450 notes

·

View notes

Text

BUY THEM NOW‼️‼️‼️‼️ (no luminol was used to manufacture this product. there are, however, traceable amounts of reagent serum. handle with precaution.)

saw someone do this with jayvik and got very inspired. more furry re-ani, LPS version!! im actually insane over them. im slowly losing it and they are consuming my life

their actual designs for context under cut :3

#re-animator#art#furry#furry art#fanart#reanimator 1985#herbert west#dan cain#lps#littlest pet shop#insane crossover#herbat west strikes once again#i wanna make them irl but i dont have bats OR squirrels amongst my lps. theyre also mad expensive. god damn#I JUST REALIZED I COULDVE ADDED HERB'S GLASSES AS AN ACCESORY IM SO STUPIDO

99 notes

·

View notes